|

Residential |

|

Aero

Series

|

|

Commercial

|

|

Guardian |

| Accessories |

Barcelona

Residential and Tahoe Commercial

|

||||||||

|

||||||||

|

||||||||

|

Part 2 Products 2.01 Manufacturer: The fencing system shall be (Residential, or Commercial) strength Aluminum Ornamental Fence as manufactured by Delgard Premier Aluminum Fencing, 8600 River Road, Delair, NJ 08110. The fence shall be Delgard's style (A,B,C,D,E,F & G) in residential strength or (M,T,P,L,S or W) in commercial strength. The color of the fence system shall be (black, white, bronze or hunter green). 2.02 Materials: A. Aluminum Extrusions: The horizontal rails of the fence system shall be extruded from 6061-T6 (or an equivalent performing alloy registered and recognized in the Aluminum Standards and Data book produced by the Aluminum Association) with a minimum ultimate strength of 38,000 psi. Pickets and posts shall be extruded aluminum manufactured from 6061-T6 alloy (or an equivalent performing alloy registered and recognized in the Aluminum Standards and Data book produced by the Aluminum Association) with a minimum ultimate strength of 22,000 psi and a minimum yield strength of 16,000 psi. B. Fasteners: All fasteners shall be stainless steel with zinc dichromate coating for enhanced corrosion resistance. Phillips head screws shall be used to attach the pickets to the rails while self-drilling, self-tapping phillips head screws shall be used to connect the rails to the posts. All screw heads shall be painted to match the finish of the fence. C. Accessories, All castings used for post caps, finials, scrolls, and latches shall be made from either zinc or aluminum. Only stainless steel fasteners may be used with these accessories. 2.03 Finish: A. Pretreatment: Before the finish is applied, a five-stage Pretreatment must be applied to assure maximum adhesion and corrosion resistance; Stage 1: High alkaline cleaner to prepare the surface Stage 2: Water rinse Stage 3: Combination of chromic, phosphoric and hydrofluoric acids that produce the chrome-phosphate conversion coating for maximum adhesion and corrosion resistance. Stage 4: Water rinse Stage 5: Water rinse B. Coatings! After the Pretreatment, the metal is dried and the paint is then applied. The fence system shall have an electrostatically applied baked on flexible acrylic finish that meets or exceeds industry standard tests. C. Tests 1)AAMA 603 (covers test procedures for pigmented organic coatings on extruded aluminum) 2) AAMA 605 (covers high performance organic coatings on architectural extrusions and panels) 3) ASTM D2247 (Humidity resistance of 1,000 hours) 4) ASTM 8117 (Salt spray resistance of 1,000 hours) 5) Accelerated weathering for 500 hours under Method 6152 of Federal Test Method 141 shall show no adhesion loss, with only slight fading, chalking and water staining. 6) Outdoor weathering shall show no adhesion loss, checking or crazing, with only slight fade and chalk when exposed for one year in Florida facing south at a 45 degree angle. 7) Minimum hardness of 2H using ASTM D3363 2.04 Construction: A. Horizontal rails: Rails shall be 1" square channel for residential grades or 1-5/8" square channel for commercial grade. Pickets shall pass through holes punched in the top of the rail. The rail shall have a top wall thickness of .055" and side wall thickness of .080" (residential) or .070" (commercial) top wall thickness and .100" side wall (commercial). The number of rails will vary according to grade, height and

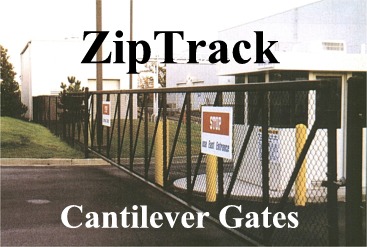

B. Pickets: Pickets shall be fastened to the rails using stainless steel screws painted to match the color of the fence. Screws shall be used on only one side of the rail, leaving the other side with a clean appearance. Pickets shall be 5/8" square with a .050" wall thickness for residential, and 1" square with a .065" wall thickness for commercial. Welding the pickets to the rails will not allow the fence to rake and is unacceptable. C. Posts: Posts shall be 2" square with a .060" wall thickness for residential or 2-1/2" square with a.075" wall thickness for commercial. Gate posts for residential shall be 2" square with a .125" wall thickness, while commercial gate posts shall be either a 6" square with a .188" wall thickness or a 4" square with a .125" wall thickness. A gate requires a gate post on both sides. A cast aluminum post cap comes standard with all posts. D. Gates: Swing gates, Rolling gates and cantilever gates shall be fabricated according to the manufacturer's standard methods. Walk gates shall be self-closing and self-latching. E. Strength: Assembled sections must be able to support a minimum of 300 pounds (residential) of vertical load at the midpoint of any horizontal rail without permanent deformation, while commercial grade must be able to withstand a minimum of 1,000 pounds without permanent deformation. Residential strength is available in heights of 36", 42", 48", 60" and 72". Commercial strength is available in heights of 48", 60", 72", 84" and 96". 2.05 Warranty: The entire fence system shall have a limited lifetime warranty against defects in workmanship and material while the finish must also carry a limited lifetime warranty against cracking, chipping or peering. Part 3 Execution: 3.01 Installation: All material must be checked upon receipt at the job site prior to installation to check for any damage that may have occurred during transport. The fence system must be stored in a safe and dry environment so as to protect it from any potential damage. This aluminum Ornamental Fence system must be installed in accordance with manufacturer's standard procedures.

|

||||||||

Fax or E-mail footages for quotes or call 1-800-878-7829 Discount

Fence Supply, Inc. |